How a textile manufacturing unit improved machine utilization, reduced downtime by 25%, and achieved 15% energy savings using Zyphion to track real-time machine ON/OFF status, runtime hours, and maintenance alerts.

The Challenge

The Challenge: Machines That Worked — and Waited — Unnoticed The factory's operational floor housed over 60 motors driving blowers, pumps, and spinning frames.Operators often switched machines ON long before production started — or left them running during idle periods between batches.The result? Rising energy consumption. Irregular maintenance schedules. Overused machines breaking down while underused ones sat idle. There was no reliable way to track actual runtime, idle hours, or switching frequency for each asset.Maintenance decisions were based on assumptions rather than real data.

Our Solution

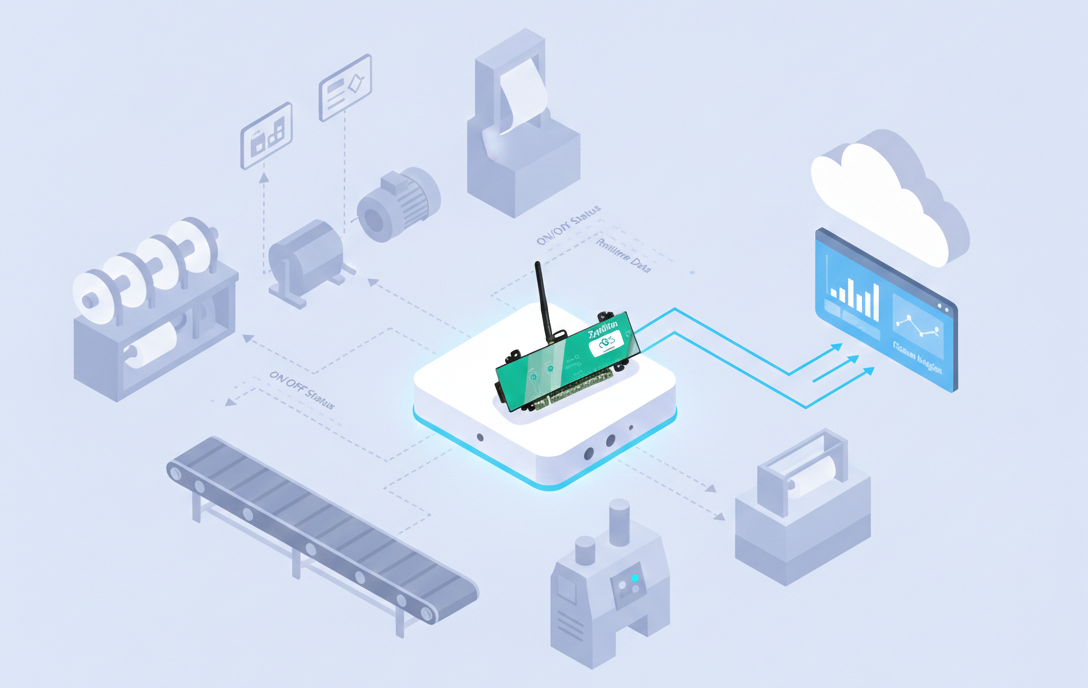

The Turning Point: Installing Zyphion Volkkommen Industries deployed Zyphion, a compact IoT-based equipment utilization device designed to monitor real-time ON/OFF status, frequency, and total operational hours — all without altering existing electrical systems. Each machine's control relay output was connected to Zyphion's input, allowing it to sense when the machine started, stopped, or tripped.Using Wi-Fi communication, Zyphion sent continuous operational data to V-VAC cloud platform, where plant engineers could instantly view: Which machines were ON or OFF. How long each had been running. How many cycles or trips occurred in a shift or day. Alerts for excessive run-hours or unexpected stoppages. With no disruption to production, Zyphion quietly began turning raw machine activity into actionable insight. Inside Zyphion: Data That Drives Maintenance Intelligence Zyphion isn't just a status monitor — it's a machine utilization intelligence system.Through its advanced firmware and cloud integration, the factory gained: Real-time dashboards showing machine status and duration. Historical data visualization to study daily, weekly, and monthly usage patterns. Threshold-based maintenance alerts, prompting service before failures occurred. Custom reports in Excel or PDF for shift-level performance analysis. Supervisors could now identify underperforming sections, compare utilization ratios, and plan rotational machine use to balance operational load.Maintenance teams received email notifications when any machine approached its set service hours — preventing overuse and unplanned breakdowns.

Key Results

The implementation delivered measurable improvements across operations, efficiency, and cost reduction:

The Results: Clarity, Control, and Continuity

Within just a few weeks, the factory reported significant improvements:

25% reduction in unplanned maintenance downtime.

15% energy savings, as idle machines were identified and switched off.

Improved production planning, with real data on machine availability.

Maintenance scheduling accuracy, ensuring timely servicing.

Extended equipment lifespan, thanks to balanced runtime across assets.

Zyphion gave the management the power to see their operations differently — not just as moving machinery, but as measurable, optimizable systems.

The Impact: Turning Machine Hours into Operational Insights

For the textile plant, Zyphion wasn't just a monitoring device — it became a decision-making tool.With every ON/OFF event logged, every hour counted, and every alert delivered, the facility built a new culture of data-backed maintenance and operational discipline.

From reducing idle power to optimizing work schedules, the management now tracks machine utilization, downtime, and performance trends — all from a single, intuitive dashboard.

At Volkkommen Industries, Zyphion represents a new generation of machine intelligence — one that helps industries move from reactive maintenance to predictive awareness, turning every runtime hour into a story of efficiency and reliability.