How a packaging unit reduced compressor energy consumption by 18% using SEDAC Lite and V-VAC to monitor pressure, flow, and power—eliminating leaks, balancing loads, and optimizing compressed air performance in real time.

The Challenge

The Challenge: Rising Energy Bills, Hidden Inefficiencies Compressed air systems are energy-hungry by design — and for this factory, the problem had become too costly to ignore.Operators noticed compressors running even during idle shifts, unbalanced load-sharing between units, and unexplained pressure drops that slowed production lines. Despite having Modbus-enabled pressure transmitters and flow sensors installed, there was no unified monitoring system to visualize what was happening in real time.By the time inefficiencies were discovered, thousands of kilowatt-hours had already been wasted. The management needed a way to see air consumption live, identify leakages, and optimize compressor performance — without replacing existing instruments.

Our Solution

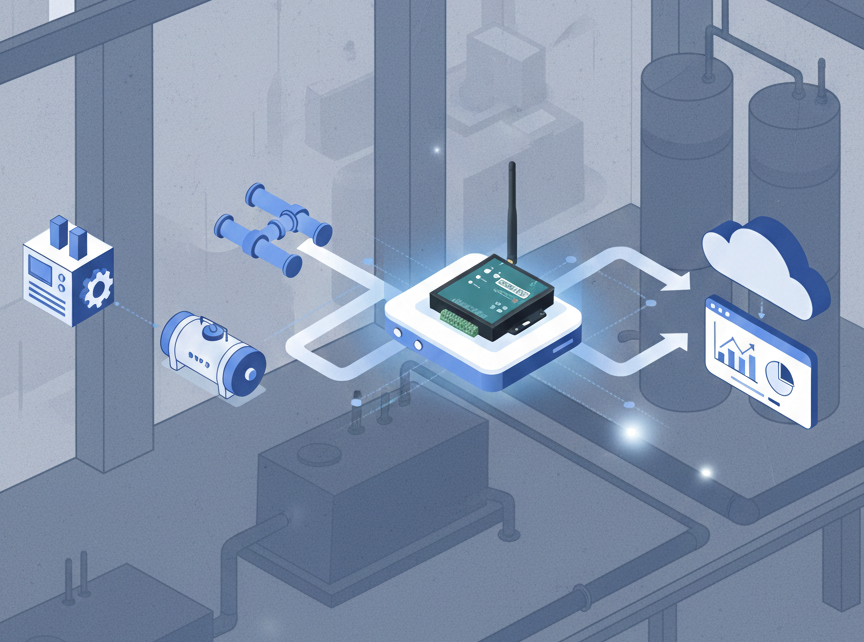

The Turning Point: Deploying SEDAC Lite Volkkommen Industries deployed SEDAC Lite, a compact IoT gateway built for seamless data communication between field instruments and cloud dashboards. Each SEDAC Lite unit was connected to: Pressure transmitters monitoring main and branch air lines. Flow sensors tracking total air consumption. Energy meters measuring compressor power draw. Through Modbus RTU communication, SEDAC Lite gathered live readings from all devices and transmitted them securely via Wi-Fi to the V-VAC cloud platform — where engineers could monitor compressor health and air demand in real time. Inside SEDAC Lite: Turning Data into Decisions SEDAC Lite acted as the digital nerve center of the compressed air network.Using its multi-protocol support and threshold-based alert system, the device made it possible to: Track pressure fluctuations and detect air leaks instantly. Correlate flow vs. power consumption to calculate compressor efficiency. Identify load/unload cycles to balance compressor utilization. Set alerts for abnormal pressure drops or excessive run-time. V-VAC dashboard provided historical trend graphs, enabling engineers to spot recurring issues like low discharge pressure during peak hours or compressors running unloaded overnight.

Key Results

The implementation delivered measurable improvements across operations, efficiency, and cost reduction:

The Results: Efficiency That Spoke for Itself

Within three months of deployment, the results were remarkable:

18 % reduction in overall compressor energy consumption.

Elimination of major air leaks, verified through real-time flow tracking.

Balanced compressor usage, extending equipment life.

Faster troubleshooting, as maintenance teams received instant alerts.

The factory's monthly power bill reflected the change immediately — saving both energy and operational stress. What once required hours of manual inspection was now visible live, 247, through a single dashboard.

The Impact: Smarter Air, Smarter Operations

The packaging unit didn't just improve efficiency — it redefined how it viewed energy management.By connecting its sensors through SEDAC Lite, the company gained data-driven visibility into one of its most overlooked utilities.

Now, every pressure spike, load cycle, and energy fluctuation tells a story — one that the factory can finally read, understand, and act upon.

At Volkkommen Industries, SEDAC Lite continues to empower industries of all sizes to make their processes leaner, safer, and smarter — proving that even the air we can't see can deliver measurable value when connected with intelligence.