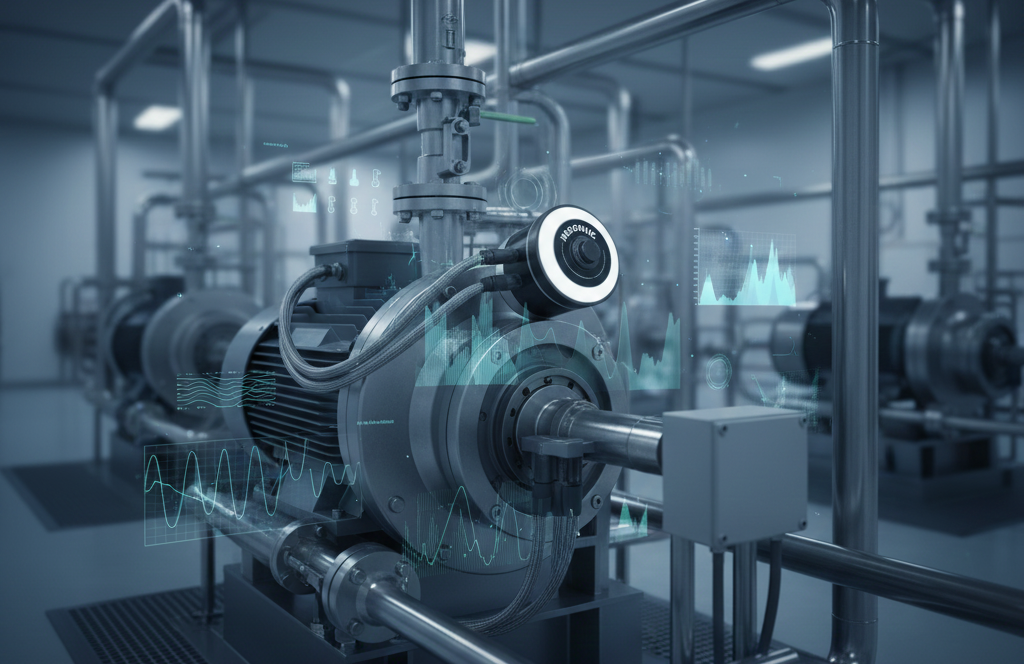

Discover how a chemical manufacturer reduced failures and downtime using Mesonic, an IoT-based machine health monitoring solution that listens to vibration, temperature, acoustics, and RPM for predictive maintenance.

The Challenge

The Hidden Problem Beneath Routine The plant relied on dozens of pumps to move process fluids across multiple sections of its chemical production line. These pumps worked continuously under varying pressures and loads.Despite routine inspections and planned shutdowns, unexpected equipment failures were frequent — often caused by unnoticed vibration spikes, rising temperatures, or mechanical looseness. Manual monitoring could not keep up. By the time a problem was visible, it had already evolved into costly downtime. The maintenance team needed a way to detect early warning signs, predict breakdowns, and extend equipment life through accurate, real-time insights.

Our Solution

The Turning Point: Introducing Mesonic To address this, the facility partnered with Volkkommen Industries, implementing Mesonic, a next-generation IoT-based machine health monitoring solution.Compact and intelligent, Mesonic continuously measures vibration, temperature, acoustics, and RPM, providing a comprehensive picture of machine behavior. Each device was installed at key pumping and rotating equipment locations, collecting high-frequency vibration data along the X, Y, and Z axes, along with skin temperature and acoustic patterns.This data was transmitted securely to V-VAC IoT platform, where engineers could view real-time dashboards, set threshold alerts, and analyze trends from any location. Inside Mesonic: Turning Raw Signals into Actionable Insights At the heart of Mesonic lies an advanced FFT (Fast Fourier Transform) analysis engine that converts raw vibration signals into frequency patterns.This helped the team identify specific mechanical issues before they caused failure: High-frequency peaks signaled bearing wear. Low-frequency harmonics indicated imbalance or misalignment. Temperature rises correlated with mechanical friction or improper lubrication. Acoustic resonance exposed early signs of cavitation within pumps. Mesonic's real-time monitoring and threshold alerts gave the team visibility they never had before.The platform displayed live health scores, trend graphs, and event logs, allowing maintenance engineers to trace each anomaly to its root cause and respond proactively. From Data to Decisions Over time, the system revealed patterns that reshaped how maintenance was done: A pump with mild vibration variance showed early bearing looseness weeks before failure. A motor with temperature fluctuations during night shifts indicated intermittent overload conditions. Acoustic irregularities in a transfer line revealed suction cavitation long before process efficiency dropped. By combining Mesonic's continuous monitoring with the engineering team's field experience, the plant achieved a new level of operational intelligence — where every machine's data told a clear story about its condition and needs.

Key Results

The implementation delivered measurable improvements across operations, efficiency, and cost reduction:

The Results: Predictive Maintenance Becomes Reality

The deployment brought measurable outcomes:

40% reduction in unplanned maintenance incidents.

30% decrease in maintenance costs through condition-based scheduling.

20% increase in average machine uptime.

Improved process safety, as temperature and vibration limits were tightly controlled.

Beyond immediate cost savings, the plant built a digital maintenance history for each asset — creating a foundation for predictive analytics and lifecycle optimization.

Beyond Pumps: Expanding the Horizon

Encouraged by the success, the facility expanded Mesonic's use to compressors, agitators, and gearboxes, integrating all devices under a unified monitoring dashboard.By doing so, they established a plant-wide machine intelligence network, offering engineers real-time insights into performance, energy consumption, and reliability trends.

The plant's management now uses Mesonic data to optimize spare part planning, schedule proactive interventions, and analyze long-term performance metrics across all assets — turning maintenance into a strategic decision-making process rather than a reactive one.

A New Chapter in Smart Manufacturing

What began as a pump monitoring initiative has evolved into a digital transformation milestone for the chemical industry.With Mesonic, the facility now operates with foresight — where vibration, heat, and sound translate into early warnings, and data becomes the foundation of reliability.

At Volkkommen Industries, this project exemplifies how industrial IoT and predictive analytics empower industries to move beyond routine maintenance — unlocking smarter, safer, and more efficient operations through continuous machine intelligence.