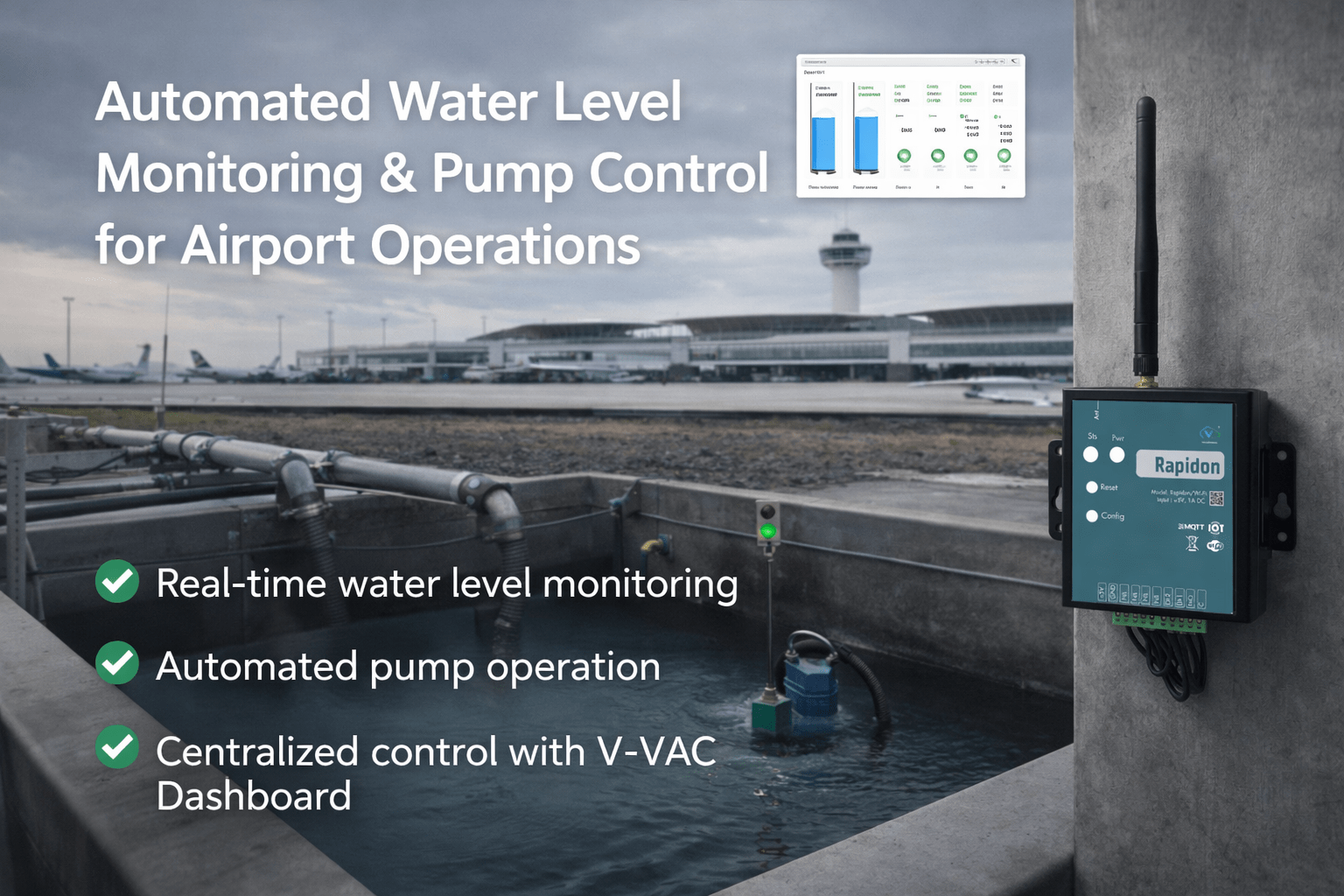

IoT-based water level monitoring and automated pump control solution implemented at an airport, enabling real-time tank visibility, dry-run prevention, and centralized pump control for uninterrupted operations.

The Challenge

Challenge Airports operate with continuous and highly variable water demand across multiple zones such as terminals, utilities, fire-fighting reserves, and service areas. The client faced operational challenges in managing water levels across multiple sumps and drinking & non-drinking water tanks, where monitoring and pump operation were largely manual and reactive. Key challenges included frequent pump dry-run risks, delayed response to abnormal water levels, lack of real-time visibility into tank levels, and limited centralized control of pumps. Manual monitoring increased dependency on personnel, introduced delays during peak operations, and posed risks of water shortages or overflow conditions both critical concerns in an airport environment where operational continuity and safety are paramount.

Our Solution

Our Solution We implemented a Water Level Monitoring and Automated Pump Control Solution tailored for the airport's operational requirements. The scope included the supply and installation of float-based level monitoring devices across sumps and both drinking and non-drinking water tanks. These sensors continuously capture real-time water level data and transmit it to the centralized system. To automate operations, pump controllers were installed and integrated with the level monitoring logic. Pump operation is now dynamically controlled based on predefined water level thresholds, ensuring automatic start/stop actions without manual intervention. This prevents dry running, avoids overflows, and optimizes pump usage. All data and control logic are visualized through the V-VAC Dashboard, which provides real-time visibility of water levels across all monitored tanks and displays the operational status of each pump. The dashboard enables operators to monitor the entire water infrastructure from a single interface, improving response time and operational clarity.

Key Results

The implementation delivered measurable improvements across operations, efficiency, and cost reduction:

Key Results

Achieved real-time visibility of water levels across all sumps and drinking & non-drinking water tanks, eliminating the need for manual level checks and reducing operational dependency on site personnel.

Enabled fully automated pump operation based on actual water level conditions, ensuring timely pump start/stop actions and consistent water availability across critical airport zones.

Prevented pump dry-run and overflow conditions by enforcing predefined level thresholds, improving pump safety and extending equipment life.

Improved operational reliability during peak airport operations, where uninterrupted water supply is essential for terminal services, utilities, and safety systems.

Centralized monitoring through the V-VAC Dashboard provided operators with a single interface to view tank levels and pump status, resulting in faster fault identification and response.

Reduced manual intervention and operational delays, leading to more efficient use of manpower and better coordination between maintenance and operations teams.

Improved overall water management discipline, supporting better planning, traceability of pump operation, and long-term infrastructure reliability.